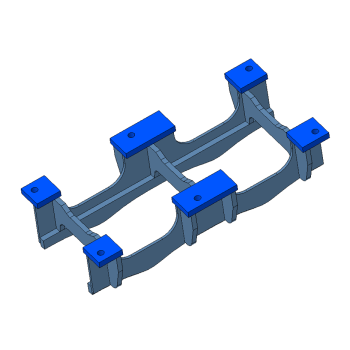

Tunnel Track Guard

The Mining class of machines works in large mines under severe working conditions. Any breakdown in this class of machine other than planned maintenance leads to severe loss to the user of these machines.

Mining equipment calls for different kind of knowledge and expertise in the development of structural parts. These structures are heavy in construction and involves welding of castings, forgings and alloy steels. Hence special care is needed in pre-heating and welding. RSB has experience in development of heavy structures up to 85 tonne class of Mining excavators. RSB has developed Centre Frames, Tail Frames and Sides frames for the Mining Class machines.

Product Features

RSB has the capability to Manufacture various kinds of Track Guard Mining class Excavators (120 Tonne Class). Has dedicated fixtures and Twin column Machining centre ensuring most cost-effective method in manufacturing of Arms of wide range and different type of application for Excavators.

RSB’s inhouse develop and manufacturing facilities (under one roof) for laser cutting, oxy cutting, plasma cutting, bending, rolling, robotic welding and machining provides better product integrity with following specification.

Product specification

-

Model: Range From 20T to 120T

- Arm size (L X W X H) in mm: Range from (395 X 380 X 180 To 1030 X 605 X 330)

- Arm Weight in Kg: Range From 40 Kg To 170 Kg